1095 is a very simple high carbon steel that is easy to shape by forging; it lacks some of the manganese of the other 10XX series and thus has a slightly lower hardenability. It added carbon creates a carbon rich martensite with plenty of free carbide for good abrasion resistance. The downside of the extra carbon is that it requires more care in the heat treatment, avoid lamellar annealing and overheating.

Recommended Working Sequence For 1095

Forging: heat to 2100°F (1150°C) . Do not forge below 1500°F (815°C).

Normalizing: Heat to 1575°F (855°C). Cool in still air.

Annealing: Heat to 1475°F (800°C). Furnace cool to 1200°F (650°C) at a rate not exceeding 50°F (28°C) per hour.

Grinding or Machining

Hardening: Austenitize- Heat to 1475°F (800°C). In thicker sections can be quenched in water or brine with extreme care but can also be oil quenched in sections under 1/4 in. (6.35 mm) thick as the preferred method.

Tempering: As-quenched hardness of approximately 66 HRC. Hardness can be adjusted downward by proper tempering.

Polish

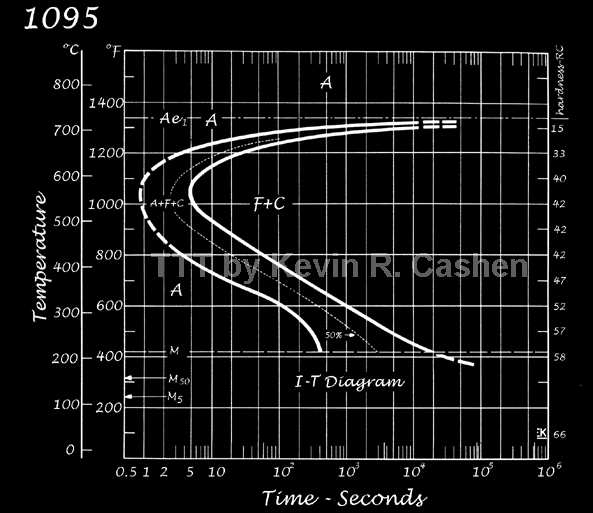

I-T / TTT diagram for 1095:

The following tempering guidelines apply to 1095 that has been hardened to industrial standards. Knifemakers using other methods will have to adjust the resulting hardness numbers downward for the same temperatures.

| Tempering Temperature | Rockwell

Hardness |

||

| oC | oF | HRC | |

| 149 | 300 | 65 | |

| 177 | 350 | 63-64 | |

| 204 | 400 | 62-63 | |

| 232 | 450 | 61-62 | |

| 260 | 500 | 59-60 | |

| 288 | 550 | 57-58 | |

| 316 | 600 | 55-56 | |

| 343 | 650 | 53-54 | |

*The above information is based upon personal experience and testing along with data from ASM International, Carpenter Steel and Crucible Service Centers.